The Efficiency of Vannamei Shrimp FCR for Successful Cultivation

Feed management is one of the determinants of the success of vannamei shrimp farming. To know about this efficiency, we must first calculate the vannamei shrimp FCR.

FCR or feed conversion ratio, is the result of calculating the effectiveness and efficiency of the stocked feed. Through FCR calculations, you can find out whether the feed given is actually eaten by the shrimp or is left over and becomes a waste.

In Indonesian, FCR is also known as rasio konversi pakan, which can indicate the level of efficiency of feed management in every cultivation that is carried out. The smaller the FCR number, the more efficient the feed management is.

Therefore, let’s learn what FCR is and how to calculate it below.

Also Read: Do These 5 Things for Successful Vannamei Shrimp Cultivation

What is Vannamei Shrimp FCR?

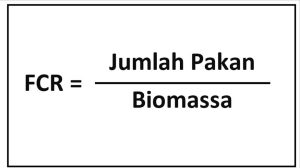

Feed conversion ratio or FCR is the calculation of the total weight of artificial feed divided by the cultivation’s total weight (biomass). In vannamei shrimp, the ideal FCR value ranges from 1.1-1.2. The smaller the FCR value obtained, the greater the profit obtained by the farmers.

Not only vannamei shrimp but FCR also applies to other aquaculture commodities, such as catfish, salmon, etc. In contrast, the high or low FCR is determined by the type of feed, species, animal size, feeding practices, water conditions, and the run culture system.

The Importance of FCR in Vannamei Shrimp Cultivation

The feed conversion ratio (FCR) is an essential metric in vannamei shrimp farming because it can provide information about the feed’s efficiency during cultivation.

The low number of vannamei shrimp FCR indicates that the feed given to vannamei shrimp is well absorbed and makes cultivation more profitable from an economic and sustainability point of view.

Conversely, a high FCR indicates that the feed is inefficient and can lead to increased costs and lower profits for the farmer. In addition, a high FCR number also harms the environment, especially in terms of water pollution.

Also Read: Vannamei Shrimp Probiotics and Its Benefits for Cultivation

How to Calculate Vannamei Shrimp FCR

To calculate FCR in vannamei shrimp farming, you must first determine the amount of feed given to the shrimp and then measure the weight gain of the shrimp over a certain period.

FCR is then calculated by dividing the feed given to the shrimp by the increase in shrimp biomass. The Feed Conversion Ratio (FCR) formula is as follows:

For example, the shrimp biomass that you cultivate is 1 ton (1000 kg). While the amount of feed that has been given is 1.2 tons (1200 kg). Then the FCR of vannamei shrimp is 1200: 1000 = 1.2.

Tips for Vannamei Shrimp FCR Efficiency

Adjusting feed distribution is crucial to maintain an optimal FCR (Feed Conversion Ratio). Several aspects need to be considered to achieve efficient FCR, including:

1. Shrimp Needs and Age

Feeding Vannamei shrimp must align with their needs and age. For instance, for shrimp younger than 15 days, it is recommended to provide powdered feed for easier digestion. Meanwhile, during the 16-45 day DOC (Day of Culture) period, crumbled feed is more suitable.

Fundamentally, the types of feed for Vannamei shrimp vary, depending on nutritional requirements, feed size, and shrimp age.

2. Feeding Methods

Feeding can be done manually by direct spreading or using an autofeeder. In choosing a feeding method, consider the feed quantity, schedule, and ensure even distribution throughout the pond. Accumulation of excess feed can affect water quality.

3. Feeding Frequency

Apart from considering shrimp needs and age, the frequency of feeding plays a crucial role. The time interval between feedings should allow shrimp enough time for digestion, ideally 48-90 minutes. The digestion process itself takes around 4-6 hours before becoming waste.

For shrimp younger than 15 days, feeding three times a day is sufficient. For shrimp aged 16-30 days, feed four times a day in accordance with their feeding capacity during that phase.

When shrimp surpass this age, feeding can be increased to five times a day. This is based on the consideration that the dissolved oxygen conditions in the pond are still optimal.

Also Read: 3 Family Favourite Sweet and Sour Shrimp Recipes

Successful Vannamei Shrimp Cultivation with DELOS

The feed conversion ratio (FCR) can indicate successful vannamei shrimp farming. This requires that farmers cannot be careless in managing feed management.

To make your vannamei shrimp farming easier, DELOS offers Farm Management to manage your shrimp ponds. DELOS is the best science, technology and operational management-based aqua-tech company that can help your vannamei shrimp farming succeed.

DELOS Farm Management is also integrated with the AquaHero application, making it easy for every farm owner and personnel to monitor their shrimp ponds daily.

Also, DELOS has an integrated supply chain program, DELOS AquaLink, which can help you get and sell pond products at the best price and quality.

Contact the DELOS Team via contact@delosaqua.com or submit your questions about vannamei shrimp farming through our website contact column at www.delosaqua.com. Succeed in vannamei shrimp farming with DELOS!